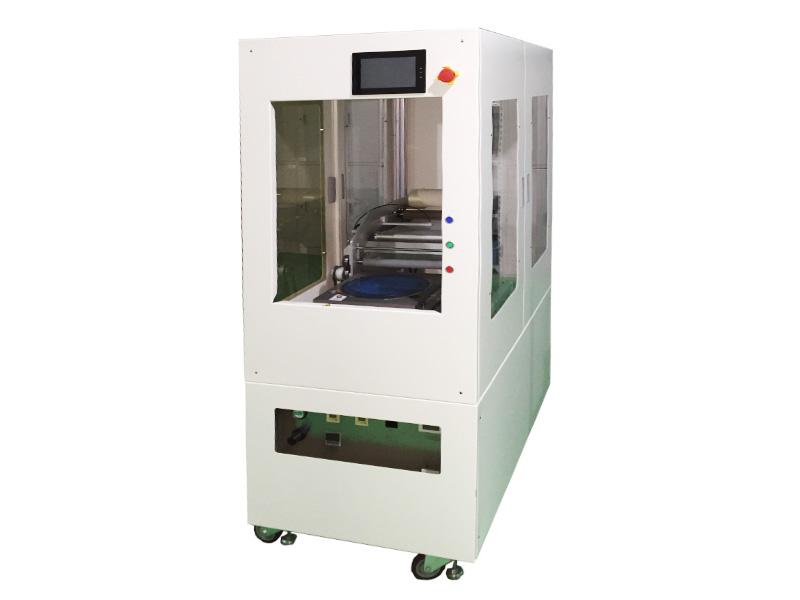

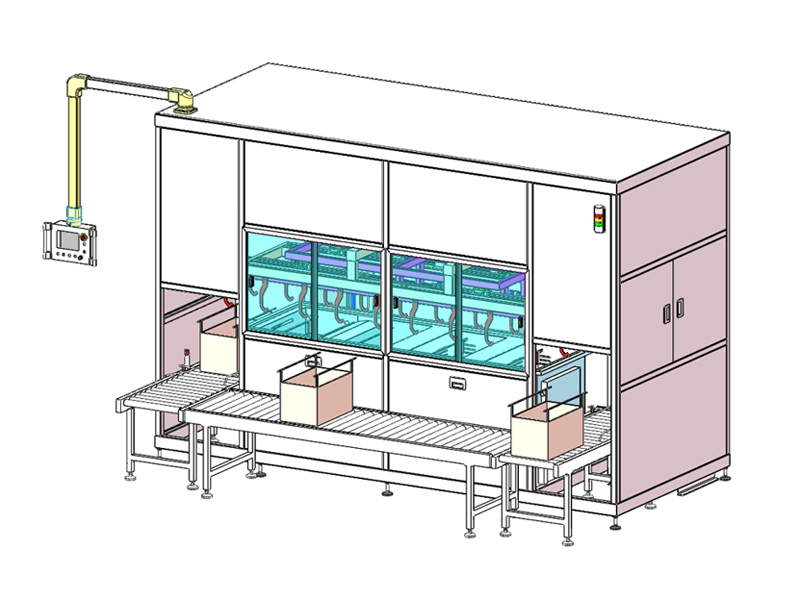

Clip washing machine

⇨ Feeding

⇨ Ultrasonic cleaning

⇨ Ultrasonic secondary cleaning

⇨ Drying

⇨ Secondary drying

⇨ blanking

- Technical Data

- Overview

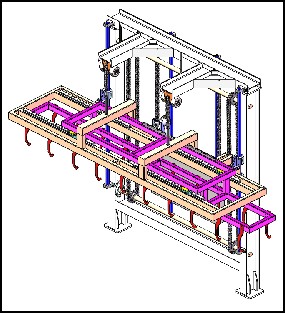

Robot arm part

The main functions of the robotic arm are:

The robot arm lifts the material frame from the drum line to the ultrasonic cleaning tank for cleaning. After the cleaning is completed, the material frame is lifted to the drying tank for drying, and the cleaned material frame is lifted to the drum line for output.

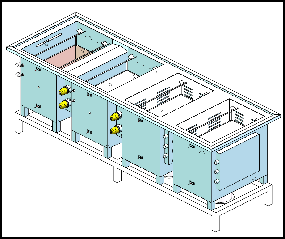

Tank part

Temperature sensor: real-time monitoring of the working temperature in the tank.

Liquid level sensor: When the liquid level in the tank is detected to be low, it ensures that the ultrasonic vibration plate and the water tank heating tube will not be dry vibration and dry burning.

Excess level drainage box: When the liquid level in the tank is high, the excess water can be drained through the drainage box to ensure the required liquid level in the tank.

Water tank heating pipe: heat the water in the ultrasonic tank to the required working temperature.

Air heating tube: heat the circulating air in the drying tank to accelerate the removal of residual moisture attached to the material frame after cleaning.

Blower: Provide a steady stream of clean air into the drying tank.

Water filtration: When the water circulates in the tank, it filters the impurities.

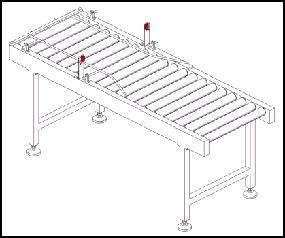

Roller part

Proximity switch: to detect whether the material frame is in place.

Through-beam photoelectric: when the detection material frame is hoisted, no new material frame will enter the hoisting area.

Guide mechanism: guide the material frame to the hoisting area and position it.

Power motor: provide transportation power for the drum line.